Learn about Shipyard Transporter

Author: Supro Trailer Date: 2019.07.03

Learn about the Shipyard Transporter

The axle of SGD Shipyard transporter consist of Independent bearing suspension structure, Double tyres installation axle(12.00R20), Hydraulic suspension four or three support points can be switched. The whole shipyard transporter consist of Power system, Hydraulic run system, Hydraulic steering mechanism, Braking system, Hydraulic lifting suspension mechanism, Frame, Electrical system, Electrical control system. Adopt hydrostatic drive, full hydraulic independent steering and hydraulic suspension. The cargo platform lifting is controlled by imported electromagnetic proportional valve to achieve the stable lifting function. The machinery is used for shipyard ship body transport. The running system adopt micro-electronic control, so the transporter is very flexible.

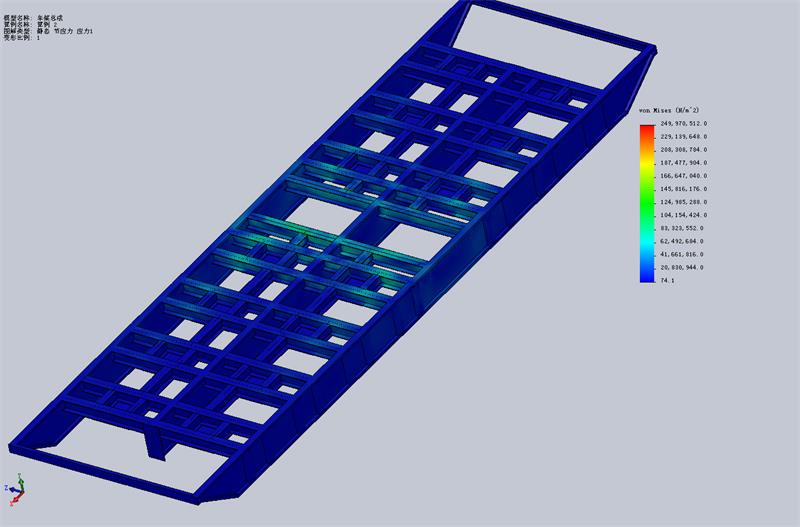

The transporter frame is designed according to the shipyard ship body segmented transport requirements.

The principles of our design are standardization, universalization, serialization, save energy and environmental protection.

1. Application

The shipyard transporter is designed for severe working surroundings of the shipyard beside the seaside, such as the salt fog in the wet atmosphere. Also in order to transport section of ship body or other material.

2. Running road surface

Cement, asphalt or other compaction road.

3. Vehicle structure

The loading weight should distribute on the load platform in balance. Please refer to the loading distribution picture.

When designing the structure of the frame, we already take consider of the stability of the loading. To guarantee the rigidity and intensity of the frame, we adopt the whole reinforce double H style welding frame! For operation safety, we pay more attention to steel structure and all the protect measures of the suspension while designing.

It has good flexibility strength of the main beam design to guarantee the four points of hydraulic bearing system stability. Otherwise, you can switch to three points hydraulic bearing system by manual operation according to individual shipyard transporter special requirements.

The frame paved skid resistance riffled plate, also equipped detachable ladder for climbing.

Adopt good quality and high strength material.

Welding can meet international standards requirements and request.

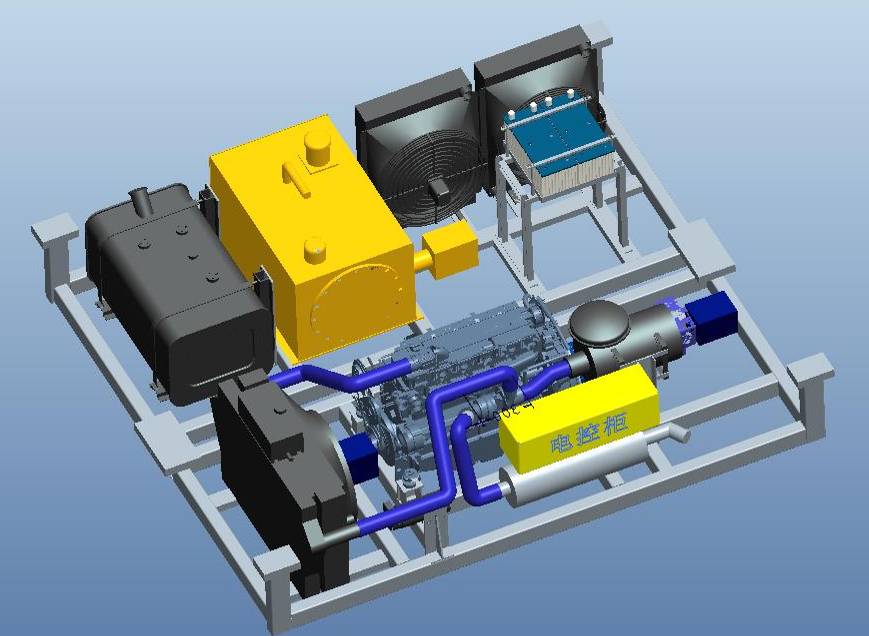

4. Power system

The power system consist of diesel engine, hydraulic oil pump, fuel tank, oil, water cooker and other parts are installed in the middle of the vehicle where immovable frame. We already think over the accessibility of the machine maintenance fully. It has a good operation and maintenance rooms to make conveniency for inter the frame bottom to do the repair and maintain of the power unit.

The reinforce power system installation frame is for full protection of power system inner complex parts and pipes system .

Adopt stable and reliable element, Deutz or Commins Water cooled engine, imported KTR coupler, imported STIEBEL transfer box and imported Rexroth Oil cylinder.

The diesel oil tank has a high capacity, precise liquidometer, and safety and convenient oil filler.

The route of transmission of power: Engine→→Driving pump→→Pressure oil→→Motor→→Reducer of wheel edges→→Wheel;

Engine→→Steering and Lifting pump→→Pressure oil→→Steering and suspension cylinder→→Gear rack steering mechanism or suspension mechanism.

The mechanical energy of engine can translate into hydraulic system pressure energy, and the engine cascade closed pump/open pump/ heat dissipation gear wheel pump directly. Other wise, for braking system, the engine has a power take-off hole to provide power for air compressor to achieve braking function. The hydraulic pipes install 10micron filter, when stucked by impurities, the control panel has clues, please change the filer in time.

5. Hydraulic system

The vehicle hydraulic system consist of Motion drive, Steering, Suspension, Heat dissipation and other systems.

The drive hydraulic system consist of Variable pump, High speed motor, Hub reduction gear and combined to a closed system. Adopt hydrostatic drive, consist of Hub reduction gear and Hydraulic motor, every hydraulic drive motor adopt respectively control ways to control the slip resistance of drive axle, to avoid some fault of the axle.

The drive hydraulic control system is closed system,consist of Variable pump, Slippage pump, Spill valve, Control valve and Cooling system to become a closed circulation, so the structure is compact and the transmission performance is steady. According to the vehicle actual load and switch the gears by the operation handle to change the displacement of motor, to meet the heavy and light weight corresponding speed requirements. Also through pedal plate can change the rotate speed of the motor while changing the working parameter of electronic control variable main pump.

The power parts integrate into the front end of the power unit, and the route of drive system power delivery is Engine-Variable displacement piston pump-Hydraulic motor-Hub reduction gear-Drive wheel.

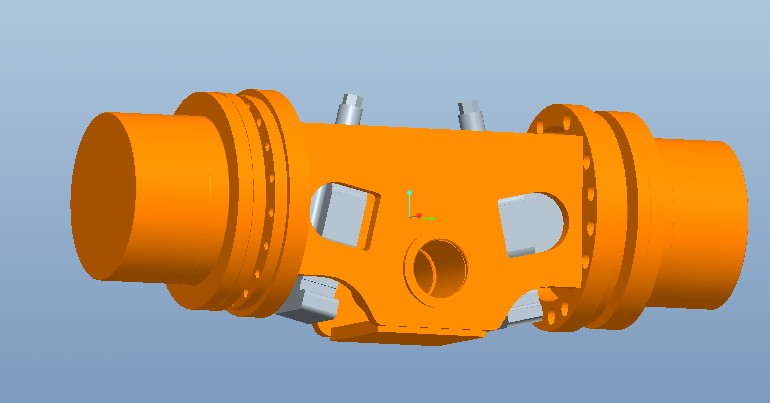

Drive axle draft

The drive axle is made by our factory, it adopt the frame structure, the middle axle hole is linked with balance beam, the safety factor of structure design is over 3 times, limited lateral oscillation angle is ±4°, the reduction gear and motor use international famous brand Rexroth or Sauer.

Steering, suspension hydraulic system is an open system, every steering suspension achieved the precise close-cycle control by steering oil cylinder drive and microcomputer. The suspension adopt hydraulic suspension, the lifting or leveling function is controlled by handle control magnetic valve operation.

The cooling system is that independent gear pump drive the radiator to make the hydraulic oil radiate heat in circulation.

The design of hydraulic pipes system is excellent, it has a good discharge capacity and heat-sinking capability, also the pipes has a strict and efficient filter system to guarantee the clearing of oil pipes, and it can protect most of hydraulic elements. The piping layout is very clear to distinguish and repair also will never twist together.

The hydraulic oil tank has a big volume to guarantee the oil mass and heat radiating area. The filling and pouring oil month all has self-closing valve filter which is convenient to change and no need oiling.

The position of every pressure gage and oil tank gauge is convenient for watching.

In the main joints of the pipes, it sets up pressure gage to make convenient for maintain and repair.

We guarantee no leaking situation in the hydraulic system

6. Steering system

Every steering axle can adjust the turn angle respectively.

The control system can do the real-time monitoring and control every axle`s turn angle to guarantee every steering axle turning is in the allowable range, then to guarantee the tyre do the pure rolling all the time. As a part of self-diagnostics system, it can analysis the fault and change the broken parts in the shortest time!

The system sets up turning angle error self-adjust program, when the error is 2°, the vehicle is keep walking; if it is 3-6°, the steering speed of suspension will slow down; but if the error is 8°, the shipyard transporter will stop running.

The steering mechanism can guarantee every steering axle has ±105°rotation.

Installed electric multi-steering modes system can guarantee more different steering modes as the below picture shows:

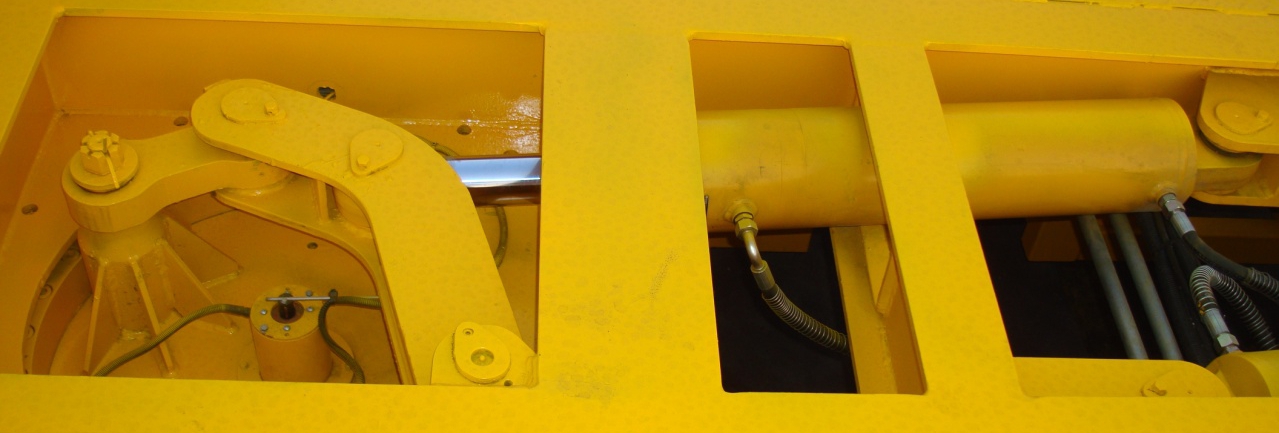

7. Suspension lifting system

Consist of multi-independent hydraulic suspension.

Full hydraulic suspension can make all the axle share the loading.

Relative to the vehicle frame, the full suspension are three or four bearing points.

The full hydraulic suspension can adjust the height of cargo platform to achieve the whole vehicle integrated lift or lift every set of suspension.

The lifting system and steering system of hydraulic suspension is interlocking, and also can relieve the interlocking. So that in the running process, it can adjust the height and balance of platform.

It installs four stop valves in the vehicle body, and can control the four points are descended by manual operation respectively.

The high-pressure hose of suspension installs anti-rupture double pipes safety valve.

The adjustment range is ±350mm.

To guarantee the height of the vehicle is above 200mm when the vehicle running in the lowest position.

8. Axle

The drive axle is high welding structure, and the design is very suitable for dismount the hydraulic motor and reducer easily and also for arrange the hydraulic pipes. The tyre are Chinese Double coin brand, and the model is 12.00R20. The rim is special enhanced model 8.5-20.

The drive axle is manufactured by professional axle factory.

9. Braking system

10. Drive system

All the instruments and operation elements install in the drive room for easy control. In the operation panel, it has running control stick, steering wheel, start/close engine bottom, packing brake, steering mode, lifting model, restart slope, running speed, aloud, emergency bottom and keys of remote control switch bottom.