If you want to customize a self propelled traveling system for your big machine, Supro Trailer is your best option!

❐Supro Trailer has produced a 300 tons self propelled traveling system for a wharf crane. If you want to customize another self propelled traveling system for your crane and other machine, Supro Trailer always be your good option!

▣Supro Trailer has mature technology on hydraulic system of heavy transporters even the self propelled modular trailer and shipyard transporter. We design the 300 tons traveling system of wharf crane against on our Shipyard transporter.

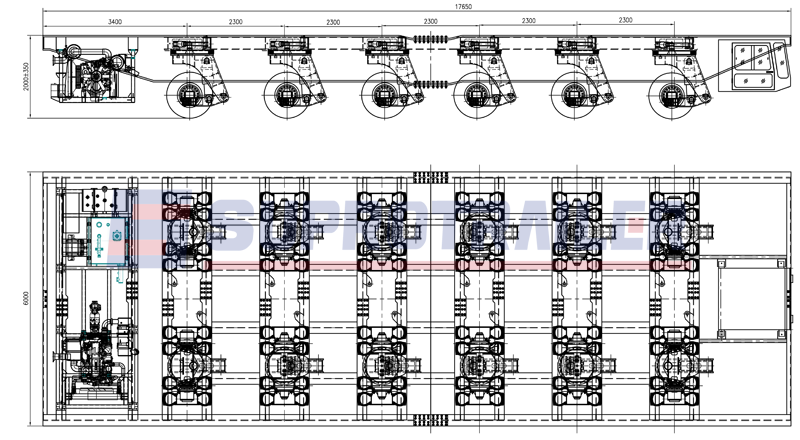

Drawing of the original system of shipyard transporter▼

▣Our company has a strict quality control system during the manufacturing and commissinning. For example, before we use each hydraulic cylinder and suspensioin, Supro Trailer make oil pressure testing to make sure each of it is qualified! So our company provides superior quality of the heavy transporter to our clients! Our company is the unique factory in China who has experience on European and USA market.

▣About the self propelled modular trailer, it has rare manufacturers except for European companies who is able to design and produce it. If you are going to buy it from European companies, the price is very expensive and also the delivery time is too long. Never mind the customized self propelled traveling system, the price is flying is the sky. Nobody in developing country is able to afford it, because the profits of crane projection is cheap in there. The price of Supro customized traveling system has a huge advantage than European one! More important is that Supro Trailer is able to provide stable performance and good quality traveling system to your machine! You can set your heart free on cooperation with Supro Trailer!

Photos of the Self propelled traveling system of crane▼

Specifications of the Self propelled traveling system

1. Main Technical Data

|

Technical payload |

Approx 320,000 kg |

|

Dead weight of transporter |

Approx. 60,000 kg |

|

Gross weight of transporter fully loaded |

Approx约380,000kg |

|

Axle Files |

2 |

|

Axle Lines Both Side |

6x2 |

|

Number of wheel bogies |

12 |

|

Wheel bogie load |

Approx约. 32,000kg |

|

Driving wheel bogies |

3 |

|

Brake wheel bogies |

6 |

|

Free Wheel Bogies |

3 |

|

Tires |

48x 12.00-24 solid tyre |

|

Diesel engine |

Type QSM11-400

400HP/294kW

Tier 3 |

|

Max. traction |

110x3=330 kN |

|

Gradient ability fully loaded |

6 % |

|

Max. speed loaded |

Approx. 5 km/h |

|

Max. speed unloaded |

Approx. 12km/h |

|

Platform height lowered |

Approx. 1,600 mm |

|

Lifting stroke wheel bogies |

Approx. 700 mm |

|

Platform height in driving condition |

Approx. 1,900 mm |

|

Axle load compensation |

± 350 mm |

|

Platform length |

Approx约13,000 mm |

|

Platform width |

Approx约.9,800 mm |

|

Fuel Tank Capacity |

500L |

|

Hydraulic Oil Tank Capacity |

600L |

2. Main Supplier List

|

Diesel engine |

Type CUMMINS QSM11-400

Tier 3 |

|

Hydraulic pump driving |

Rexroth A4VG250EP4D1

Displacement: 250 cc/rev

RPM:2200

Peak Pressure: 420bar

Quantity: 1 |

|

Hydraulic Pump Lifting/Steering |

Rexroth A11VO100LRDS

Displacement: 130cc/rev

RPM:2200

Peak Pressure: 280bar

Quantity: 2 |

|

Hydraulic motors |

Danfoss H1B110

Displacement: 110cc/rev

Quantity:6 |

|

Panetary gears |

OMCI MRM111S2

Ratio: 47.07

Max Input Torque: 611Nm

Max Output Torque: 29313Nm

Quantity:6 |

|

Proportional Multiway Sandwich Valve |

HAWE PSV SERIES

|

|

Control system |

Hesmor |

|

Tooth and Pinion Steering Mechanism |

Type to be determined

12units |

|

Hydraulic Cylinder Lifting |

China with Parker Sealing

Cylinder Dia. 210mm

Piston Dia.200mm

Stroke; 345mm

Pressure Max: 315bar

12units |

|

Hydrauic Cooler |

Lengfan China, |

|

Flex-coupling system |

KTR/STIEBEL or equal |

|

Tires |

China Supplier 12.00-24 solid tyre |

|

Battery |

China made

Type to be determine,

2 units |

|

Hydraulic hoses and fittings |

Eaton or equal |

|

Steel structure main frame |

Self Made |

|

Steel structure wheel bogies |

Self Made |

3. Cabin:

a) Driver Seat at the Left in the cabin and Drive Right Side on the road.

b) Noise in Drive Cabin Shall be no more than 75dB

c) Left side door. Locking able.

d) Both side back mirror. Adjustable.

e) Rain Wiper with water spray.

f) Cooling Air Conditioner and Heater(May not need Heater in Cabin because Huston is at Subtropical area)

g) Roof light

h) Adjustable chair: front and back. Backrest angle.

i) Pressure Gauge shows: Driving, Lifting and Steering Pressure, Brake System Pressure.

j) Engine RPM, Temperature both hydraulic and engine water, Fuel Volume and other key data will show on the monitor screen.

k) Main Operation:

General Power Switch with key.

forward backward handle

lifting joystick

accelerator pedal and brake pedal.

Parking brake handle,

steer wheel,

Fast/slow mode switch.

Lifting and Steering Mode buttons

l) Monitor screen for operation.

m) Monitor screen for corner camera to watching the blind area.

n) Fire extinguisher

4. Light: HeadLights(near and far), width indicators, backward indicators, brake indicators, turn indicators(Lift and Right), evolving lights, maintenance lights.

Head Lights and Back Lights shall be bright enough for at least 8 meters distance no less than 100Lux(to be discussed)

5. Horn, backward alarm, travelling alarm.

6. Steering Mode: Multi-way steering by tooth and pinion steering mechanism. Including normal drive; diagonal drive; cross drive; circular drive; truck steering and rear or front end steering;

7. Lifting Mode: Equal lifting; relative lifting; Lifting to driving Height(equal mode); Manual individual lifting of each corner or each side;

8. Dual line anti explosive valve protection system;

9. 3-4 Point Support Switch-able;

11. Chassis Weld by Material Q345B; Covered by Aluminum Remove-able Plate with 4~5mm at Top.

12. Hydraulic Cylinder brake system drum brake. Parking and Service Brake.

13. Anti spinning drive.

14. Extra electric power minimum 1kW supply in PPU for extra light connection for maintenance.

15. All 4 corners shall have cameras mounted; a revised camera shall be installed. Monitors position installed inside the driving cabin.

16. Back Mirror Adjust-able via remote control in Cabin. Back Mirror can be fold to reduce the rotating radius while passing the critical area.

17. Screw less than 12mm shall be Stainless 304 or higher grade.Screw more or equal to 12mm shall be DACROMET treated. Washer shall be anti-loose type DIN25201.

18. High Pressure Hydraulic Oil Filter 10Micro;

19. Final Coat Color RAL1023 Traffic Yellow;

Surface Treatment: Shoot Blast to Sa2.5

Coat: according to ISO12944, Paint quality must meet the requirement of C5-M, life time equal or more than 15 year, the dry film thickness must be no less than 320um.

attached C5-M operation guide line.

20. Over Load test: 1.25 Static and 1.1 Dynamic;

21. Hydraulic pipes carbon steel painted, must clean before installation.

22. Hydraulic Joints by Bite Type Tube Fittings;

23. Hydraulic oil tank carbon steel must be chemical treated.

24. Additional Measure such as accumulator or manual pump, to release the Parking Brake, in case of Engine or Hydraulic system failed to be functional, the Carrier shall be possible to move to maintenance workshop by pulling by tractors

In any case of the transport brake down or lose power, the drive motor shall have a function of bypass to allow the whole transporter to be able to be towed.

in any case the transporter lost its function of driving there must be a way to manually adjust the wheel axle steering angle so correct direction can be keep to let tow away is possible.

consider all above the chassis must consider tow point which is easy access and strong enough to be towed even it is full heavy load, both front and rear.

25. All Hoses must be protected by spiral rubber-protective sleeve.

26. Cylinder bearing is self-spherical bearing but need also lub point.

Related links of Supro Trailer:

1. Production of Supro Self propelled modular trailer

2. Production of Supro shipyard transporter